TEL: +86-18651008520

TEL: +86-18651008520Email: liuhao@jyganghao.com

TEL: +86-18651008520

TEL: +86-18651008520 Current location:Home > Products

Current location:Home > Products

Technical parameter:

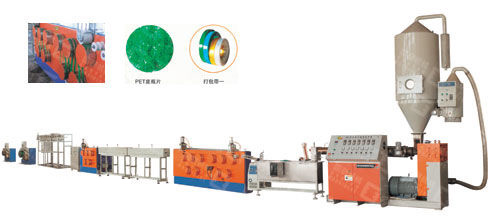

1. Raw material: PET bottle flakes (or PET pellets)

2. Product: PET strap

Width: 9mm-22mm

Thickness: 0.6mm-1.5mm

3. Output:

80-100kg/hr with one mould

160-180kg/hr with two moulds

320-400kg/hr with four moulds

4. Workers: 2 -3 workers per shift, 12 hours/shift.

Characteristic:

1) Raw material PET flakes are crystallized by CSG series drying system, its dew point of -40¡æ makes the moisture no more than 40PPM, what's more, this device can increase the viscosity of the PET flakes.

2)The extruder adopts the special screw for PET flakes, the screw's unique separation and mixing ability ensure the materials are plasticized more even; Thanks to the meter pumps the dosing and steady extrusion assure even length and width of the straps.

3) The mould with different standards; Leakage is eliminated after the improvement of the melt exchanger.

In addition, We will provide the turn-key basis sales services to our customers, once the customer places the order, our company is responsible for the line for one year's maintenance, training and Know-how technology for operation.